Shell and tube heat exchanger

Shell and tube heat exchanger

The shell and tube heat exchanger is an important equipment in the process of oil refining, chemical industry and electric power. According to the statistics, the equipment accounts for about 40% of the total static equipment. It is the main equipment in the process, but also enterprises to reduce energy consumption, the main means to reduce the cost of the shell and tube heat exchanger technology is one of the main symbol of the advanced degree in oil refinery.

Alves, as the leading manufacturer of heat exchanger equipment industry in China, is the manufacturing of shell and tube heat exchanger (20 thousand tons). The company has People's Republic of China special equipment (pressure vessels D1, D2) design and manufacture permit license, with hundreds of kinds of specifications of shell and tube heat exchanger products, professional demand for different industries in different areas. From product design, manufacturing, testing and inspection services to the entire process in accordance with the ISO9001 international quality system requirements and GB150-2011 "," GB151-2014 "pressure vessel heat exchanger", "pressure vessel safety technology supervision regulations" provisions.

Shell and tube heat exchanger is one of our main products, there are a lot of originality in the heat exchanger structure design, manufacture and application of technology; in addition to the conventional shell and tube heat exchanger design and manufacturing technology, mainly engaged in the development, efficient shell and tube type processing to enhance the heat transfer element d heat exchanger in the field of heat transfer enhancement has major technical innovation, the Alves company shell tube has the advantages of high efficiency and stable heat exchanger. Compared with the common tube heat exchanger, the heat transfer efficiency is improved, the resistance loss is reduced and the heat transfer efficiency and the resistance drop are optimized. The spiral tube, arc tube, baffle rod and spiral baffle plate and tube shell heat exchanger is developed by our company national patent product development, performance and quality for the international advanced level, the products have been widely used in oil refining, petrochemical, light industry, electric power, llurgy, water conservancy and other industries.

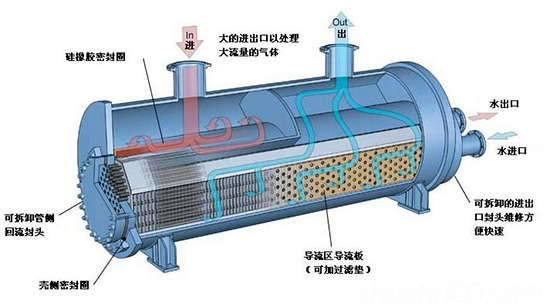

Product composition

|

The shell and tube heat exchanger is composed of the main components such as tube, shell and tube bundle. The tube bundle is the core of the shell and tube heat exchanger, and the heat exchange tube acts as the heat conducting element. Another basic element has a great influence on the thermal performance of the heat exchanger is baffle plate (or baffle rod). The casing and the casing determine the bearing capacity of the shell and tube heat exchanger and the safety and reliability of operation. |

|

|

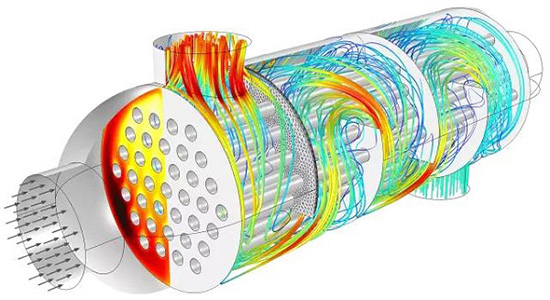

Working principle

|

|

Shell and tube heat exchanger belongs to the heat exchanger, the change of fluid channel in the heat pipe which is called tube, heat exchange tube fluid outside the channel are called shell. Tube side and shell respectively through two different temperature fluid, fluid with high temperature through the heat exchange tube of the heat transfer to the fluid at low temperature, high temperature of the fluid is cooled, low temperature fluid is heated, so as to realize the purpose of the two fluid flow and heat transfer process. |

400-655-0807

400-655-0807